How we estimated the returns to energy efficiency

The financial returns to cost-saving investments are of interest to all businesses, as well as finance providers and development partners. EMC was able to provide our client with quantitative conclusions despite limited local data when we were asked to estimate the returns to energy efficiency solutions.

This blog post is based on a 2016 EMC study, conducted with Arup, that specified and analysed the financial (and environmental) returns to Cambodian firms investing in improved energy efficiency. Our analysis was used to design a Fund to support SMEs’ investments in energy efficiency solutions.

Note: the estimates below reflect data available in 2016 and may no longer be valid.

How we estimated the returns to energy efficiency investments

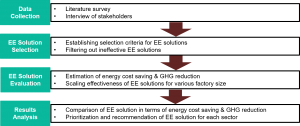

The project required us to identify and describe potential energy efficiency (EE) investments in selected industries and analyse the costs and returns of these investments. This was conducted in four phases, outlined in the figure below.

After the initial data collection stage, criteria were used to decide which type of energy efficiency investments to study. Investments were excluded where:

- the capital cost is either very small (unlikely to require our client’s assistance) or very large (unaffordable for many firms);

- the energy saving is small;

- greenhouse house reductions are small;

- implementation is difficult; and

- EE solution providers not present in Cambodia.

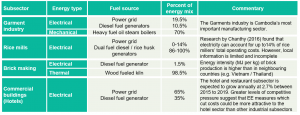

Next, EMC examined the potential energy savings and greenhouse gas (GHG) reductions for a number of Cambodian industries. Four industries were then selected for detailed analysis: garments, rice milling, brick making, and hotels. These industries were chosen because of their energy intensity and possible greenhouse gas reductions. The chosen industries and their energy mix are summarized in the following table.

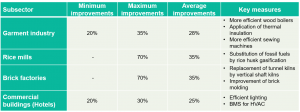

In general, there seems to be large potential for energy savings in these industries. These are summarised in the next table. Our research found that the energy efficiency solutions with the most potential in these industries include: switching fuel sources, upgrading thermal energy generation machines, and upgrading electrical equipment.

Our analysis required data on energy consumption, energy efficiency, fuel mix, and fuel price. Disaggregated data on these are scarce in Cambodia. We used a variety of sources to produce the necessary information, including: government data; case studies of individual businesses; interviews with local EE experts; existing literature on EE in Cambodia and other comparable countries. International data was adjusted for Cambodia, based on direct observations of local businesses by the engineering team.

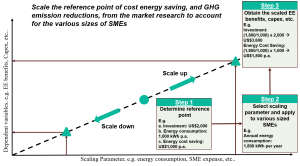

A financial model was developed based on an average business profile and a set of typical energy efficiency solutions for each industry. The information gathered was used to estimate the average capital cost of implementing a set of typical EE solutions in each industry and expected cost savings. Capital costs were then scaled for each solution in each industry to produce a cost for a typical small, medium and large business in that industry, as per the diagram below.

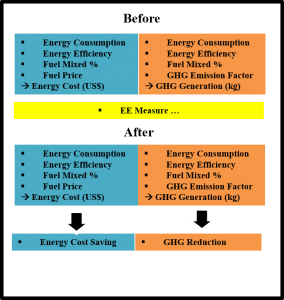

So for each industry we have a number of energy efficiency solutions, each with a percentage improvement in energy efficiency and its capital cost depending on business size. We estimate details of the various parameters for a typical business before the EE solution and after implementing the EE solution, from which we obtain cost savings and GHG reductions, as show below.

To learn about the results of this analysis, we continue in our next blog post here.

Energy efficient technology helps improve competitiveness and the environment. Our earlier blog posts described the relevant institutional environment in Cambodia, and the energy mix in Cambodian industry.

Other related EMC posts:

Challenges with Rice Husk Gasifiers in Cambodia

Select relevant reports from our client and their knowledge platform:

The Economic, Social and Environmental Impacts of Greening the Industrial Sector in Cambodia

Cambodia’s Green Growth Potential

Exploring Financial Policy and Regulatory Barriers to Private Climate Finance in South-East Asia

Comments are closed.